Table of Contents

A split-plot design is a type of experimental design used in statistical analysis to study the effects of multiple factors on a particular outcome. It is typically used when there are two or more factors that cannot be completely randomized and must be studied in separate stages or levels. In a split-plot design, the main factors are assigned to whole plots, while the sub-factors are assigned to smaller sub-plots within each whole plot. This allows for a more efficient use of resources and reduces the number of experimental runs needed.

For example, a study on the effects of different fertilizers on plant growth may have two main factors – type of fertilizer and amount of water. The main factor of type of fertilizer may have three levels – organic, synthetic, and no fertilizer. The main factor of water amount may have two levels – high and low. In a split-plot design, the main factor of type of fertilizer would be assigned to whole plots, while the sub-factor of water amount would be assigned to sub-plots within each whole plot. This allows for the comparison of all six combinations of fertilizer and water levels, while only requiring a smaller number of experimental runs. This type of design is particularly useful in agricultural and industrial research where it is not feasible to completely randomize all factors.

What is a Split-Plot Design? (Explanation & Example)

A split-plot design is an experimental design in which researchers are interested in studying two factors in which:

- One of the factors is “easy” to change or vary.

- One of the factors is “hard” to change or vary.

This type of design was developed in 1925 by mathematician Ronald Fisher for use in agricultural experiments.

To illustrate the idea of the split-plot design, consider an example in which researchers want to study the effects of two irrigation methods (Factor A) and two fertilizers (Factor B) on crop yield.

In this particular example, it’s not possible to apply different irrigation methods to areas smaller than one field, but it is possible to apply different fertilizers to small areas.

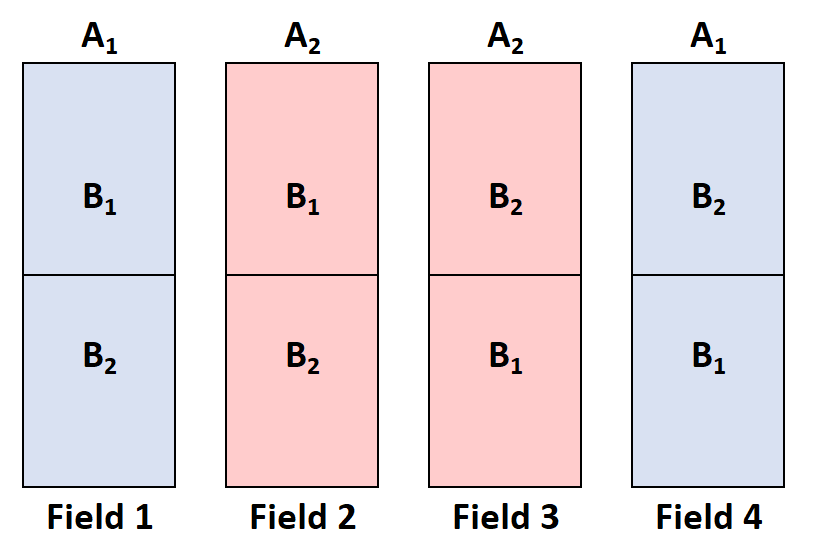

Thus, if we have four fields then we can randomly assign one of the irrigation methods (we’ll call them A1 and A2) to each field:

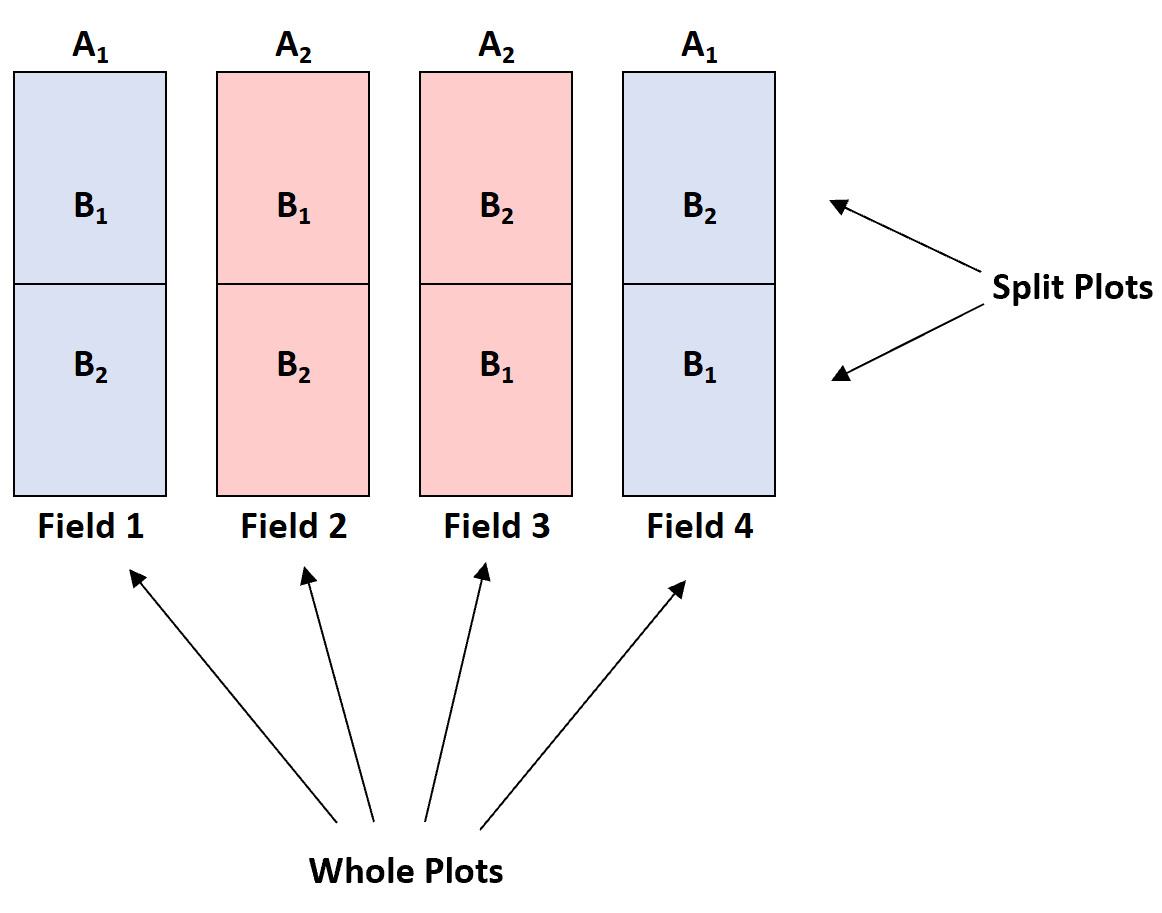

Then we can split each field in half and randomly assign one fertilizer (we’ll call them B1 and B2) to each half:

In this example, we have 4 “whole” plots and within each whole plot we have 2 “split” plots.

Advantages of Split-Plot Designs

Split-plot designs have two advantages over completely randomized designs:

1. Cost

Since one of the factors in a split-plot design doesn’t have to be changed for each split-plot, this means this type of design tends to be cheaper to carry out in practice.

2. Efficiency

A split-plot design leads to an increase in precision in the estimates for all factor effects except for the whole-plot main effects.

Examples of Split-Plot Designs in Real Life

Split-plot designs are often used in manufacturing because there is often some variable that is produced in large quantities and thus it makes sense to carry out a split-plot design to reduce the cost of running an experiment.

Here are a few examples of split-plot designs in real life scenarios:

Example 1: Baking

A packaged-food manufacturer may be interested in identifying the optimal cake mix formulation. Since cake mixes are made in massive batches, it’s not feasible to change the combination of ingredients.

Thus, the ingredients act as the “whole” plot factors and other factors like temperature and baking time are used as the “split” plot factors.

Example 2: Automobiles

An automobile manufacturer may be interested in finding the optimal engine/fuel combination. Since engines take a long time to make, they may decide to create three new engines and test out three different fuels on each engine.

In this scenario, the engine type is the hard-to-change factor “whole” plot factor and the fuels are the easy-to-change “split” plot factor.

Example 3: Woodworking

A wood manufacturer wants to find the optimal mix of wood type and temperature to produce the most durable wood. Since the type of wood can take a long time to acquire, they may apply three different temperatures to two different wood types.

In this scenario, the wood type is the hard-to-change factor “whole” plot factor and the temperature is the easy-to-change “split” plot factor.

Additional Resources

Permuted Block Randomization

Matched Pairs Design

Pretest-Posttest Design